Lider en Equipos Industriales

Proporcionando a la industria nacional, productos de la mas alta calidad con el apoyo de nuestros proveedores.

Más Información

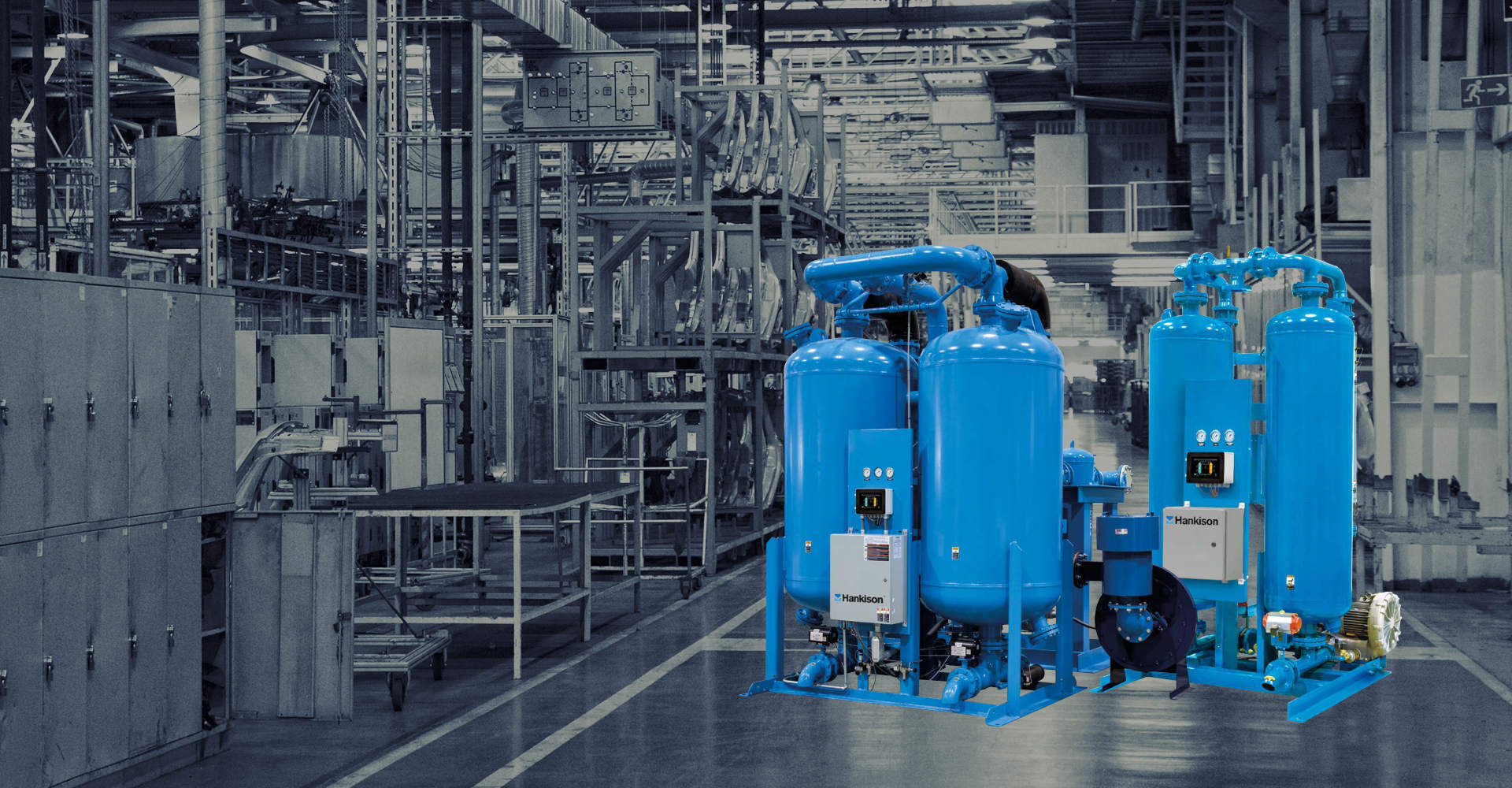

Soluciones de tratamiento de aire comprimido

Hankison proporciona una calidad de secadores refrigerativos, filtros de aire comprimido, purificadores de aire respirable, condensado y drenajes de aceite / agua separadores para mejorar la productividad y ahorrar energía.

Más Información

Nuevos Productos

Compresores de Aire

FS-Curtis le ofrece ahorros en costos en sus sistemas de Aire Comprimido.

Más Información

Atención Personalizada

Nuestro apoyo inicia en el momento en que el cliente nos presenta su proyecto o su requerimiento, ofreciendo la Asesoría para la elección del equipo adecuado según sus especificaciones, asesoría en la Instalación y Soporte, así como también la capacitación para la operación y mantenimiento requerido para asegurar el buen funcionamiento del equipo.

Contamos con un equipo de técnicos certificados por los fabricantes de cada una de las líneas que orgullosamente representamos.

Sectores Diversos

Desde los años 80’s Impulsora Zeus a desarrollado proyectos relacionados con sistemas de aire comprimido para la industria petrolera y la industria en general con la calidad y necesidades para cada uno de nuestros clientes.

Somos una empresa comprometida con nuestros clientes y proveedores, nos distinguimos por ofrecer soporte técnico, refacciones genuinas y entregas oportunas, apoyados en la amplia calidad de productos que ofrecemos y en la gran experiencia que nos distingue.

Productos para la Industria Energética y la Industria en General.

Rogers KRV Series: Compresor de aire de tornillo rotativo de 30 HP, 100 PSI.

Conjunto de compresor de aire de tornillo rotativo de alta resistencia, de una sola etapa, serie KRV de Rogers Machinery, modelo KRV-30-100, con enfriador de lubricante refrigerado por aire, montado sobre una base de acero fabricado, accionado directamente por un goteo abierto montado en brida C Motor de alta calidad, resistente y de alta calidad, optimizado para una operación de par constante. El ensamblaje se completa con todos los equipos estándar.

Contacte nuestro departamento de ventas para recibir mayor información.

Contamos con certificación de ISO 37001:2016

Contamos con certificación de ISO 9001:2015

Socios Número 56257 – Canaco Monterrey

Proveedores Oficiales de Pemex #164401

Socio Numero 8226 – American Chamber/Mexico

# de Socio: STPS / UTD / DGIFT / AR51705/2021